|

| Winston withstands the blizzard-like conditions outside of the shop |

The foul weather arrived just as the weather man predicted. Monty and I didn't let it hamper our progress. We met for breakfast at Hardee's in Meridianville and then progressed to the shop. As I moved Winston outside to make room to set up, I realized that the last time he was in some snow was on June 27, 2004. On that day we hit a blizzard between Leadville and Breckenridge, Colorado, at over 10,000 feet elevation. Conditions were less severe today.

Our first order of business was to test Monty's new drill bit to cut our 5/8" holes in both the aluminum rims and subsequently in the heel of each banjo neck. The precision of this operation ultimately determines the alignment of the strings in relationship to the frets and to the centerline of the neck and pot. The new bit worked perfectly! Within about an hour, both my neck and Monty's were bored and both rims were ready to move on to the next step. We were greatly relieved to have this step behind us. Clint is with his family this weekend, so he still has this to look forward to.

Our first order of business was to test Monty's new drill bit to cut our 5/8" holes in both the aluminum rims and subsequently in the heel of each banjo neck. The precision of this operation ultimately determines the alignment of the strings in relationship to the frets and to the centerline of the neck and pot. The new bit worked perfectly! Within about an hour, both my neck and Monty's were bored and both rims were ready to move on to the next step. We were greatly relieved to have this step behind us. Clint is with his family this weekend, so he still has this to look forward to. Monty decided to start shaping his new dowel rod, made of maple, while I proceeded upstairs to begin filing out around the 5/8" hole in my rim to make it into a square opening that my dowel rod will fit into snugly. I didn't understand why so many of the traditional banjos had square dowel rods, but I've concluded that part of the reason is to keep the neck from rocking sideways relative to the top surface of the rim -- to keep the fretted surface in transverse alignment with the head. After Monty got his dowel rod shaped he started drilling the 16 holes around the rim where the brackets attach that help apply tension to the head. He had made and polished the brass brackets during our last two building sessions. My drill press was too small to accommodate the 11-5/8" diameter of the rim, so we unbolted it from my workbench and let it hang over the edge of the bench. Then, while I held the drill press, Monty drilled the holes. It worked just fine, as you can see:

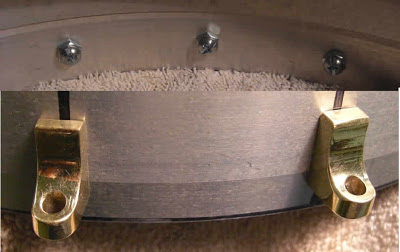

Monty decided to start shaping his new dowel rod, made of maple, while I proceeded upstairs to begin filing out around the 5/8" hole in my rim to make it into a square opening that my dowel rod will fit into snugly. I didn't understand why so many of the traditional banjos had square dowel rods, but I've concluded that part of the reason is to keep the neck from rocking sideways relative to the top surface of the rim -- to keep the fretted surface in transverse alignment with the head. After Monty got his dowel rod shaped he started drilling the 16 holes around the rim where the brackets attach that help apply tension to the head. He had made and polished the brass brackets during our last two building sessions. My drill press was too small to accommodate the 11-5/8" diameter of the rim, so we unbolted it from my workbench and let it hang over the edge of the bench. Then, while I held the drill press, Monty drilled the holes. It worked just fine, as you can see: |

| Here, you can see both the 5/8" hole for the dowel rod and the smaller holes for attaching the brackets |

|

| The inside (top image) and outside view (bottom image) of Monty's beautiful, handmade brass brackets |

|

| Filing the square hole -- An endless process |

While all the sanding and hole-drilling was going on downstairs, I spent a good part of the day hand filing the square hole needed for my dowel stick to slide through when assembling the neck to the pot. Eventually I discovered that the tapered end of my dowel rod was slightly barrel-shaped. I used the belt sander to straighten the surfaces. Then I cut the length of the round dowel end to fit snugly into the heel and I glued them together, ensuring that the neck, dowel rod, and rim are all properly aligned.

|

| The dowel rod glued to the heel of the neck |

So finally, I was able to see what the assembled banjo will look like by simply sliding the square dowel rod through the square hole into the rim:

|

First time assembly -- a glimpse of a completed banjo

|

In spite of dire predictions for bad weather, this turned into a very productive day for the Banjo Boys. 'Til next time...

No comments:

Post a Comment